If you’re a business owner or manufacturing professional, there’s a good chance that 3D printing has caused you a lot of excitement, and more than a few headaches. Maybe you’ve faced sticker shock when pricing enterprise options, or puzzled over which rigid plastics or thermoplastic wonder will last the longest. Perhaps you’ve groaned about another “rushed” prototype that somehow still took three weeks. You’re not alone. For all their revolutionary promise, traditional 3D printers often come with high costs, limited material versatility, and time-consuming prototyping.

But what if there was a 3D printing solution engineered to conquer these exact pain points? One that delivers precision and speed with the kind of engineering-grade reliability that makes your production line (and your CFO) finally relax? Well, there is one (this wouldn’t be a very good post if there wasn’t)! Welcome to the world of Stratasys FDM 3D printers, where heated build chambers, a vast material portfolio, and proven operational efficiencies are not just wishful thinking, but are miraculously the status quo.

In this article, we’ll dissect the core technologies behind Stratasys FDM, show how they solve the most pressing challenges facing modern manufacturers, compare them to alternative solutions, and back up every claim with authoritative data, expert insights, and real-world proof.

Table of Contents

- Understanding Stratasys FDM Technology: Industrial Innovation at Its Best

- Overcoming Common 3D Printing Challenges with Stratasys FDM Solutions

- Business Impact: How Stratasys FDM 3D Printers Transform Manufacturing and Production

- Stratasys FDM vs. Competitors: Why It Outshines Other Industrial 3D Printing Solutions

- Conclusion

- References

Understanding Stratasys FDM Technology: Industrial Innovation at Its Best

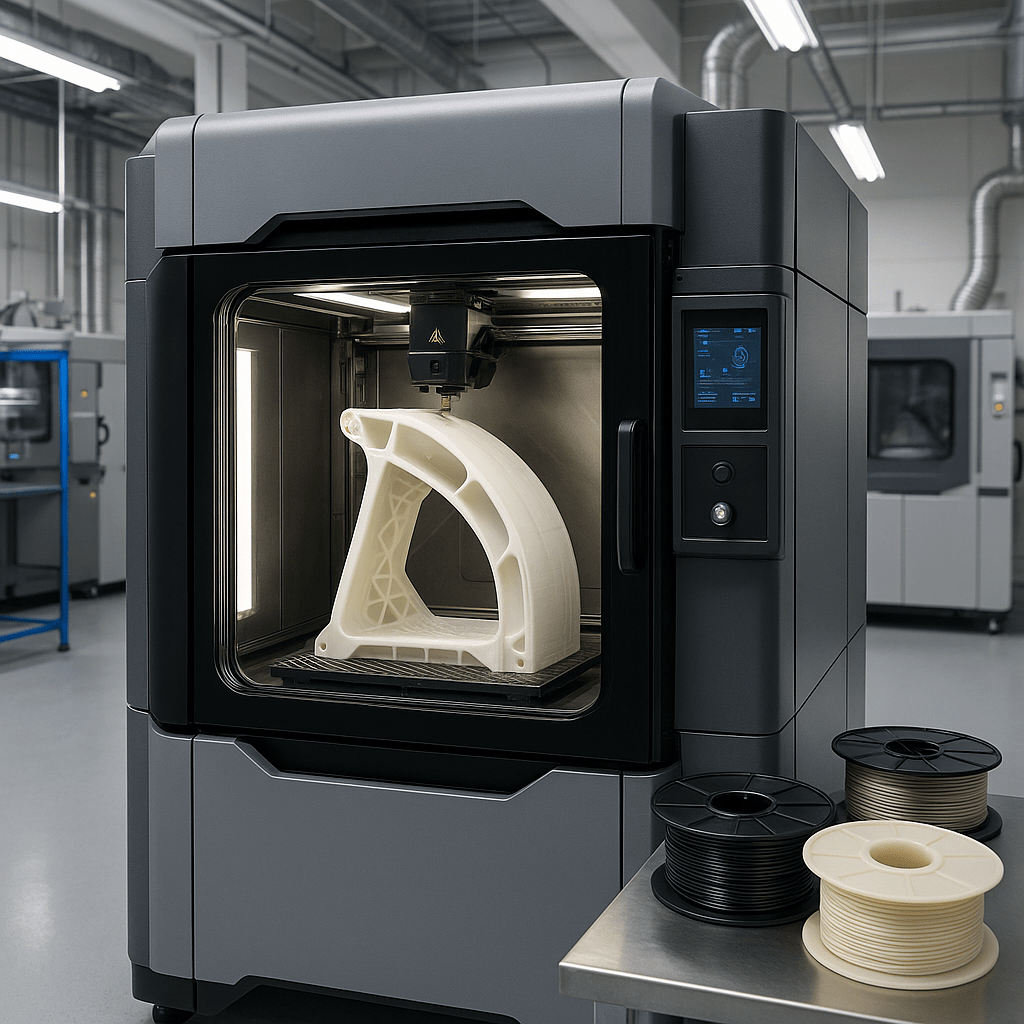

Fused Deposition Modeling (FDM) is no longer “just” a way to print cool knickknacks in your uncle’s garage. Under the Stratasys banner, FDM has been re-engineered for true industrial-grade performance, meaning your business can print end-use parts, functional prototypes, jigs, fixtures, and even aerospace components with jaw-dropping reliability.

Key technological innovations—such as the heated build chamber—set Stratasys FDM apart, directly enhancing print accuracy and repeatability. When paired with an unmatched portfolio of engineering-grade materials, Stratasys FDM answers the call for varied industry needs, from automotive, to aerospace, to advanced manufacturing.

If you’d like a foundational overview of FDM technology and where it fits in the industrial landscape, the Overview of FDM 3D Printing Technology by UC Davis is a great place to start.

What Makes Stratasys FDM Printers Distinct from Other 3D Printing Methods?

Forget the one-size-fits-all mentality. Stratasys FDM printers are designed to handle the nuanced requirements that separate prototyping from production, and hobby from industrial output.

At the heart of these printers is the heated build chamber—a Stratasys innovation that keeps the entire print at an optimal temperature throughout the process. This reduces warping and layer separation, leading to the kind of dimensional accuracy that would make even the most demanding aerospace engineer smile (or at least nod approvingly)1. While other technologies like SLA or SLS have their strengths, they often fall short on material selection or operational robustness at a factory scale.

To quote Stratasys’ own technical guide, “FDM technology is trusted for its precision, reliability, and repeatability. With printers that are at home in an office to industrial-grade platforms for the factory floor, it is one of the easiest 3D printing technologies to learn and operate. Material diversity opens your application space with capabilities bridging engineering-grade plastics to high-performance polymers1.”

Industry experts routinely note the precision and robustness enabled by this approach. As additive manufacturing professionals attest, Stratasys’ heated build chamber controls the print environment, allowing the use of engineering polymers that would otherwise warp or fail on open-bed machines, leading to ultra-consistent results across prototypes and production runs alike.

If you want to learn more about advanced solutions for 3D printing challenges, ranging from surface finish to difficult-to-print geometries, check out these Advanced Solutions for 3D Printing Challenges.

Industries Benefiting Most from Stratasys FDM 3D Printers

Stratasys FDM printers aren’t just for showrooms—they’re on the factory floors of some of the world’s most innovative companies, quietly (and not-so-quietly) reshaping how things are made.

Aerospace and defense: With tight tolerances, regulatory requirements, and materials that have to survive absurd speeds, not just any printer will do. As Bill James, SVP & GM of Space Transportation at Sierra Space bluntly states: “This vehicle will go Mach 25 upon re-entry, so speed is the nuance of our business. Speed is also valuable in building these vehicles. We like Stratasys’ team and their products because they help us do what we’re doing here, faster2.”

Automotive and manufacturing: Stratasys FDM’s heated chambers and reliability have enabled automotive giants like General Motors to swap aluminum for high-strength polymer parts, reducing part weight by 32%, and slashing manufacturing time by 80% for overhead conveyor hangers3. No more waiting months for machined metal!

Commercial manufacturing, product development, and industrial design: Engineers and product managers everywhere leverage Stratasys for jigs, fixtures, production tooling, and rapid prototyping, all with minimized risk of costly misprints or material failures.

If you’re interested in the economic side, studies on Cost Efficiency and Rapid Prototyping with FDM 3D Printing further underline these operational and financial advantages.

Key Stratasys FDM Models and Their Specifications

Not all FDM printers are created equal—and for true business impact, picking the right model matters.

Stratasys F170: Praised by users and reviewers alike for its ease of use, accuracy, and dual material support, the F170 delivers both cost-efficiency and reliability. Ideal for small to mid-scale production, this model features a build volume of 254 x 254 x 254 mm, smart software integration, and rapid material changeovers—qualities specifically called out by TriMech professional reviews4.

Stratasys F900: When size does matter, the F900 takes center stage, offering a massive build envelope of 914 x 610 x 914 mm, and compatibility with high-performance polymers like ULTEM™ 9085. Industrial manufacturers appreciate its ability to print full-scale prototypes, production tools, and end-use parts in one go, removing the need for multiple print cycles.

F123 Series: The F123 series, including the F370, balances professional-grade accuracy and affordability, enabling iterative prototyping, production tooling, and even short-run manufacturing. Reviews in Tom’s Hardware further highlight its reliability, and the tangible value brought to businesses prioritizing uptime and versatility5.

The above models all share Stratasys’ core strengths: heated build chambers, straightforward workflow, and a material portfolio wide enough to make most competitors green with envy. And if none of these are quite what you’re looking for, Stratasys does have other more specialized, potentially better fitting options.

Overcoming Common 3D Printing Challenges with Stratasys FDM Solutions

Let’s face it—traditional 3D printing can sometimes feel like buying a smoothie mixer. It looks great until you realize it only works with a few kinds of fruit, costs more than your refrigerator, and clogs the second you want to run a production batch (alright, maybe that last part was a bit of a stretch). Below, we dig into three common industry pain points and show exactly how Stratasys FDM solutions rewrite the script.

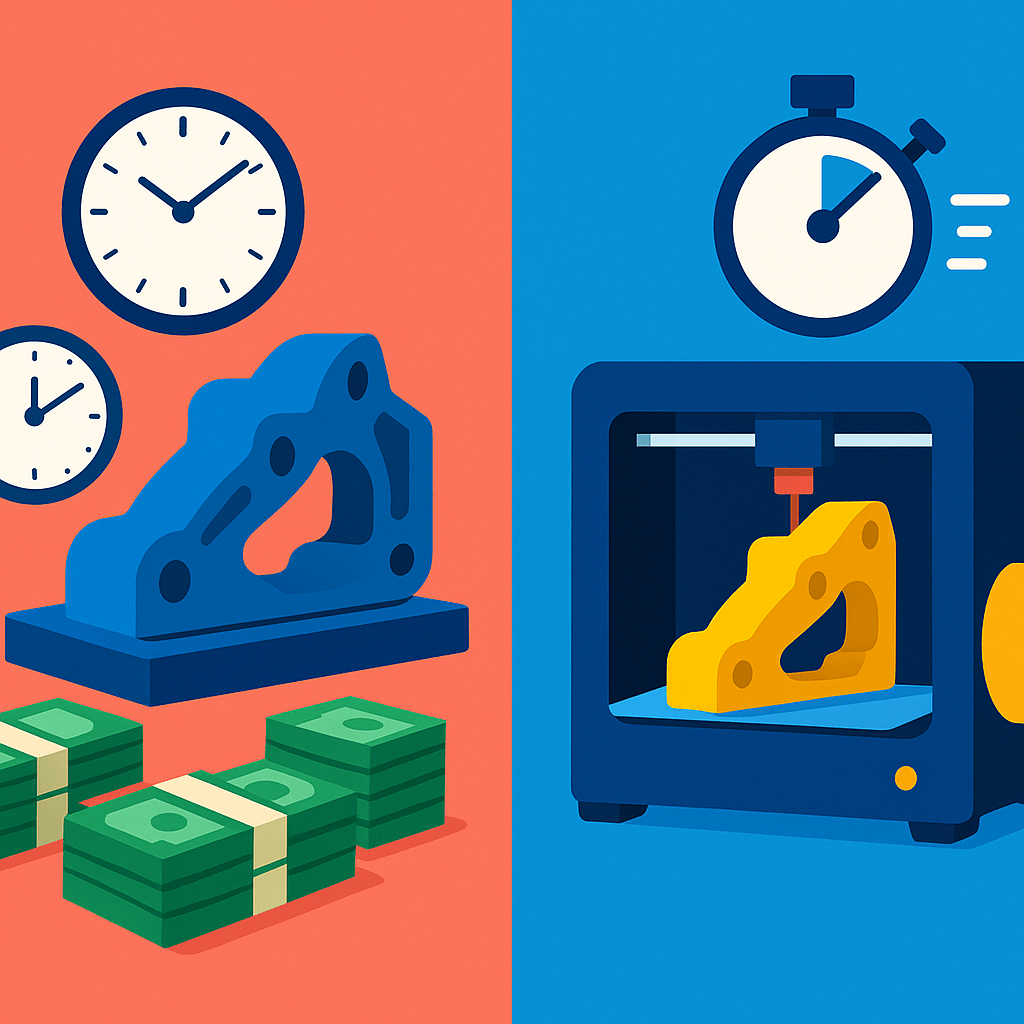

Why 3D Printing Costs Can Be High and How Stratasys FDM Cuts Expenses

The root of 3D printing’s reputation for sky-high costs? Between advanced hardware, expensive engineering-grade materials, and considerable operational expenses, the numbers add up quickly. In fact, 3D printers can range from $200 desktop units to $500,000+ for industrial systems, with professional machines typically costing up to $23,000, and enterprise units coming in at around $100,0006. Materials, maintenance, and operator training only add to the bottom line.

But here’s where Stratasys FDM delivers serious relief. Manufacturing in-house with Stratasys can cut time and expense by up to 90% for applications like composite tooling3. Case in point, General Motors replaced an aluminum part with one 3D printed on a Stratasys F900, achieving an 80% time saving, and 32% weight reduction3. Additionally, print reliability means minimized failed prints and wasted materials, further reducing operational expenditures.

Formlabs’ analysis of calculating 3D printer costs underscores that cost-efficiency is maximized when high reliability and consistent output are achieved—both boxes Stratasys confidently checks7.

For more data on this, take a look at this Cost Efficiency and Rapid Prototyping with FDM 3D Printing write-up.

Expanding Material Options: How Stratasys FDM Supports Advanced and Versatile Printing Materials

Nothing cramps an engineer’s style like a limited color palette (metaphorically speaking of course)—and manufacturing is no different. Material choice dictates everything from part durability, to heat resistance, to chemical compatibility.

Stratasys raises the bar with the broadest portfolio of FDM printing materials in the industry, featuring…

- Engineering-grade thermoplastics: ABS, PC, ASA, and more—perfect for robust end-use parts.

- Composites: Carbon fiber-reinforced Nylon 12CF and others for lightweight, ultra-strong production components.

- High-temperature and specialty polymers: Including ULTEM™ and PEI, enabling aerospace and automotive certifications.

- Emerging innovations: Stratasys frequently expands its portfolio to include cutting-edge polymers and composites1.

Carefully engineered materials from Stratasys, as well as suppliers like 3M, support even demanding environments, offering characteristics such as high chemical resistance and durability at elevated temperatures (for a deeper dive, the 3DSPRO Quick Guide to 3D Printing Materials is an excellent technical resource).

Industry experts note, “the breadth of Stratasys’ engineering polymers allows design engineers to choose the right mix of strength, flexibility, and environmental resistance for virtually any application,” substantially expanding the real-world scope of additive manufacturing. For up-to-date scientific discussions of emerging materials and multi-material capabilities in 3D printing, check out Advanced Solutions for 3D Printing Challenges.

Accelerating Prototyping: Stratasys FDM’s Role in Rapid Product Development

Prototyping bottlenecks can be a silent killer for innovation, dragging timelines and frustrating product managers. Traditional prototyping is infamous for taking 10–16 weeks (oof). With Stratasys FDM, that can shrink to days, or sometimes even just a few hours8!

The real-world figures tell the story here, Stratasys F123 series models have delivered prototyping turnaround times up to 70% faster than traditional machining, with accuracy and engineering-grade detail1. Rapid prototyping directly accelerates design iteration for products ranging from automotive assemblies to medical devices, getting concepts to market in record time.

Engineers report, “FDM-based rapid prototyping gives us the freedom to iterate, test, and refine products within days, not months—freeing up both our innovation pipeline and our production schedules.” Manufacturing studies confirm that adopting Stratasys FDM results in more flexible, faster workflows, with fewer bottlenecks and greater creative freedom.

Business Impact: How Stratasys FDM 3D Printers Transform Manufacturing and Production

It’s one thing to talk specs and savings, it’s quite another to see business transformation in action. Stratasys FDM printers have delivered measurable improvements in cost, speed, quality, and scalability for organizations across the industrial spectrum.

Enhancing Manufacturing Speed and Efficiency with Stratasys FDM

Production delays can spell disaster, especially when “just-in-time” sounds more like “just-not-quite-yet.” Stratasys drastically shortens production timelines. Composite tooling lead times have been reduced by up to 90% compared to traditional fabrication, thanks to FDM’s rapid manufacturing capabilities1,3. And Stratasys’ manufacturing webinars reveal streamlined workflows on the factory floor, with real-time production of end-use parts and jigs, shrinking both downtime and labor costs.

A recent case study—legitimately, not just hypothetically—details how General Motors used their F900 printer, executing a swift part redesign that would otherwise gum up production for weeks, if not longer3. And because Stratasys FDM printers are built for 24/7 reliability, your production team can sleep well at night.

Scalability and Precision: Meeting Large-Scale Industrial Demands

Scaling a production process while maintaining precision is a classic challenge. Stratasys FDM printers, especially high-end models like the F900, handle this with aplomb.

- The F900 is purpose-built for large-volume manufacturing, boasting a massive build chamber and material compatibility to handle multiple projects or large-size parts simultaneously.

- Repeatability and precision are engineered into the hardware, with extensive warranties and manufacturer documentation supporting claims of < 0.200 mm accuracy, even for production-scale deployments1.

- Production and design engineers note Stratasys FDM’s ability to pivot from single prototypes to short- and mid-run manufacturing, all while preserving the exact same part quality. That’s the kind of scalability that transforms “could we?” into “we already did.”

Stratasys’ focus on robustness and repeatability also means less scrap, more predictable costs, and a production line managers are actually willing to show off to executives (and, frankly, probably their parents and middle school social studies teachers too).

Stratasys FDM vs. Competitors: Why It Outshines Other Industrial 3D Printing Solutions

At this point, you might be wondering, what about the competition? Cutthroat comparisons abound in the 3D printing world, but Stratasys FDM consistently pulls ahead—especially where it matters most for business users.

Comparing Material Choices and Technological Capabilities

Many competitor 3D printers offer one or two headline features—a touch of fiber, a splash of automation—but none rival the holistic suite of technological innovation Stratasys brings. For one thing, they support a far broader array of engineering and high-performance materials than most competitors, including certified aerospace-grade and ESD-safe options1.

Further, their proprietary heated chamber technology ensures even difficult-to-print polymers and composites succeed regularly—critical for industries demanding high tolerances and robust mechanical properties1. And while some alternatives offer limited dual extrusion, Stratasys enables mixing support and build materials for both geometric complexity and strength, substantially expanding the range of manufacturing applications.

Cost and Operational Efficiency: Demonstrated Business ROI

Let’s talk turkey. Or, more accurately, ROI. Studies and verified case analyses show that businesses using Stratasys FDM for composite tooling, prototyping, or large-scale production have realized HUGE cost and time savings over conventional methods3. Dealer and third-party benchmark reviews confirm Stratasys track record for uptime, minimized failed prints, and lower maintenance needs, all maximizing operational efficiency, and reducing hidden costs.

While competitors’ content is often light on validated cost comparisons or detailed financial outcomes, Stratasys arms its prospective customers with real numbers, testimonials, and even independently reviewed whitepapers to reinforce its superior business value.

Conclusion

Modern businesses face a 3D printing crossroads. Either settle for unreliable machines, limited materials, and slow, expensive workflows, or choose a proven partner engineered for industrial transformation. Stratasys FDM 3D printers are a leap forward, not just a step. With their revolutionary heated build chambers, the broadest material compatibility in the segment, trusted industrial reliability, and data-backed cost savings, they solve the toughest 3D printing challenges—letting you accelerate product development, slash costs, scale with quality, and innovate faster than ever. So, if you’re ready to upgrade from smoothie-mixer status to powerhouse production, it’s time to consider the unparalleled advantages that Stratasys brings to the table.

References

- Stratasys. (N.D.). FDM 3D Printing – Fused Deposition Modeling – Stratasys. Retrieved from https://www.stratasys.com/en/guide-to-3d-printing/technologies-and-materials/fdm-technology/

- Stratasys. (N.D.). Explore Industrial 3D Printing Solutions | Stratasys Additive Printing. “This vehicle will go Mach 25 upon re-entry…” – Bill James, SVP & GM, Space Transportation Sierra Space. Retrieved from https://www.stratasys.com/en/

- Stratasys. (N.D.). 3D Printing Case Studies – Stratasys Support Center. General Motors Use Case. Retrieved from https://support.stratasys.com/en/Resources/Case-Studies

- Stratasys. (N.D.). Stratasys F123 Series: 3D Printers. Product documentation and TriMech. Retrieved from https://www.stratasys.com/en/3d-printers/printer-catalog/ and https://mfg.trimech.com/3d-printer/stratasys-f123-series/

- Tom’s Hardware. (N.D.). Best Budget 3D Printers 2025. Reliability findings for F123 Series. Retrieved from https://www.tomshardware.com/best-picks/best-budget-3d-printers

- Formlabs. (N.D.). How to Calculate 3D Printer Cost. Retrieved from https://formlabs.com/blog/how-to-calculate-3d-printer-cost/

- PubMed. (2022). Cost Efficiency and Rapid Prototyping with FDM 3D Printing. Retrieved from https://pubmed.ncbi.nlm.nih.gov/36339988/

- Stratasys. (N.D.). Guide to Rapid Prototyping and Additive Manufacturing. Retrieved from https://www.stratasys.com/en/resources/blog/guide-to-rapid-prototyping/